We price leather two ways:

1) Most of our leathers are priced by the each and you are charged one price regardless of size.

2) Occasionally we offer a leather that is priced by the square foot (sq. ft.) or meter and sold in the exact form we receive from the tannery (side, hide, skin, split, belly, etc). When you place an order for products priced by the sq. ft. or meter, you will be given a cost approximation in your shopping cart. After your order has been picked, this cost approximation will be adjusted to reflect the actual price based on the size of the piece as measured and marked by the tannery. Your final charge will be for the actual size of the product that is shipped to you.

We have done our best to display as accurately as possible the colors of the products shown on the Site.

However: 1) because the colors you see will depend on your monitor, we cannot guarantee that your monitor’s display of any color will be accurate. 2) colors may vary due to differences in dye lots. Always order extra if color consistency is critical to your project.

Common Terminology – Purchasing leather is not a difficult task. We offer a variety of leathers that will work well for whatever leather project you have in mind. Below you will find a list of commonly used leather terms that describe the various leathers we sell.

Aniline Dyed – Leather that is dyed all the way through with a transparent dye. Because the finish is transparent and shows the natural markings of the leather, only the best quality hides can be used.

Armor Leather – Heavy veg-tan leather used for shoe soles and for protective armor by historical re-enactors.

Bark Tanned – Also known as vegetable tanned. Leather tanned by the tannins extracted from the bark of trees.

Belly Cut (snake) – Snakeskins that are cut on the underneath so the tanned skin shows the snake’s normally visible pattern.

Chrome Free – Also known as Aldehydetanned leather, this is the leather that most tanners refer to as wet-white leather due to its pale cream or white color. Used in infant’s shoes and automobiles.

Chrome Tanned – This process uses soluble chromium salts, primarily chromium sulfate, to tan leather. Most commonly used for garments, footwear and upholstery.

Crust – Leather that has been tanned, dyed and dried, but not finished.

Distressed – Leather that is aniline dyed with one color over another (usually darker over lighter) so as to create rich highlights and an artificial aged appearance. This finishing process is intended to emphasize the characteristics of the hide such as scars, scratches and wrinkles. Also called “antiqued leather”.

Drum Dyed – The process of coloring leather by tumbling it in a rotating drum immersed in dye to allow maximum dye penetration.

Embossed Leather – Leather that has been “stamped” with a design or artificial texture under very high pressure. Our embossed leathers have textures of ostrich and gator.

Flesh Side – The underside of the animal’s hide. When looking at a piece of veg-tanned tooling leather, this will be the rough side.

Full Grain – Leather which has not been altered beyond hair removal. It is the most genuine of leathers, retaining all of the hide’s original texture and markings. The hide’s best, strongest and most durable layer.

Good Hand – A soft, supple leather that feels good to the hand.

Grain Side – This is the hide’s surface that had the hair of the animal. The grain side is used for leather carving and stamping by leathercrafters.

Hair Cell Grain – Noticeable appearance of where the hair pores were on the leather.

Kidskin – Soft leather made from the skin of a young goat.

Latigo – Cowhide leather tanned for outdoor use. Utilized for cinches, ties, and other saddlery work and for army accoutrements.

Milled – During the tanning process, the leather is tumbled in a large drum-shaped container to make it softer.

Nubuck – Leather buffed on the grain side to give a velvety surface.

Oil Tanned – Leather that is tanned using oils to create a very soft, pliable finish.

Patina – The aura or lustre that develops in leather as it ages with use.

Pebble Grain – A cosmetic character resembling small pebbles on the leather’s top side.

Printed Leather – Leather that has been “stamped” with a design or artificial texture under very high pressure.

Pull-Up Finish – Describes the behaviour of leather that has been treated with oils, waxes and dyes in such a way that when pulled or stretched, the finish becomes lighter in the those areas. Considered a mark of high quality.

Rawhide – Hides that have only been dehaired and cured but not tanned.

Semi-Aniline – Aniline leather that has a matching pigment layer added to even out the color and add protection.

Shearling – A sheepskin or lambskin that has gone through a limited shearing process to obtain a uniform depth of the wool fibers. They can be tanned with either a veg-tan method, normally used for saddles and outdoor gear, or with a chrome method, normally used for garments.

Side – Leather tanned from one half, or “side” of a full hide.

Skirting – Sides from cattle that are left in their heaviest form for use with saddle making and re-enactment armor.

Splits – Leather made from the lower (inner or flesh side) layers of a hide that have been split away from the upper, or grain layers. Split leather is not as durable as full grain leather and is normally used as suede.

Suede – Leather that has been buffed and brushed for a more attractive surface.

Temper – A characteristic of leathers defined by pliability/softness.

Tooling Calf – Normally, a very lightweight veg-tanned leather with a very clean appearance.

Top Grain – Usually refers to a process of sanding away the natural grain from a leather’s top surface. Imitation grain gets stamped into the leather for a more uniform look.

Veg-Tanned – A method of hide tanning which utilizes materials from organic materials such as bark instead of the traditional chemicals. This is the method utilized when tanning tooling leathers.

Veg-Splits – Veg-tanned leather that has been split with both sides having a fleshy feel. Cannot be tooled.

Waxy Hand – An upholstery or handbag leather that has a waxy feel and look to it.

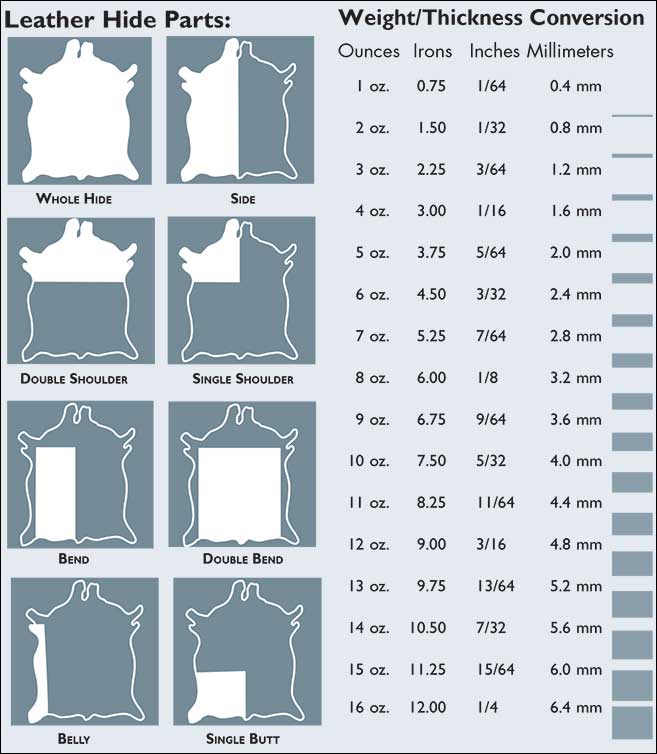

Weight – A term which describes the thickness of leather in ounces. One ounce equals 1/64th (0.4 mm) of an inch in thickness. See the chart below.

As mentioned above, leather is generally measured in square feet (sq. ft.), but some patterns call for a certain number of yards. Use the examples below as guidelines to convert the yards into sq. ft.:

The pattern calls for 3 yards of 36″ fabric. Use a conversion factor of 9: 3 x 9 = 27 Add 20% 6 Total…33 sq. ft. needed.

The pattern calls for 3 yards of 45″ fabric. Use a conversion factor of 11: 3 x 11 = 33 Add 20% 7 Total….40 sq. ft. needed.

The pattern calls for 3 yards of 54″ fabric. Use a conversion factor of 13: 3 x 13 = 39 Add 20% 8 Total….47 sq. ft. needed.

Adding the 20% allows some extra to make up for imperfections, holes or any loss in cutting.